How are porcelain biscuits made?

23.06.22

In our previous article, we explored the rich history of porcelain biscuit . This time, let's turn our attention to the techniques used to create these exceptional objects.

Before creating an object, you need the right materials. Porcelain paste is primarily composed of kaolin (70%), which gives it its whiteness. Feldspar is added to lower the melting point, and quartz for translucency. In the 18th century, this was an experimental recipe, somewhat akin to a cooking recipe. Today, the mills that prepare the paste follow a formula close to that established by Alexandre Brongniart , director of the factory in the 19th century. The minerals are ground under granite millstones until they reach the size of grains of rice. The resulting paste is then mixed with an equal amount of water and fed into a cylindrical mill filled with sea pebbles. This mill must operate for 15 to 20 hours.

The resulting slip is placed in a holding tank that is regularly agitated to prevent settling. The clay then undergoes quality control processes. It is passed through a wire mesh sieve with 0.06 mm holes. The residue remaining on the sieve, the oversize, must not exceed 2% of the production. If less than this is recovered, the clay risks collapsing during firing, while if more is recovered, the grinding is insufficient. The absence of iron is also checked using a magnet. Indeed, during firing, iron produces brown stains that spoil approximately 3% of the pieces produced. In most cases, despite all efforts, the presence of iron can only be determined after firing.

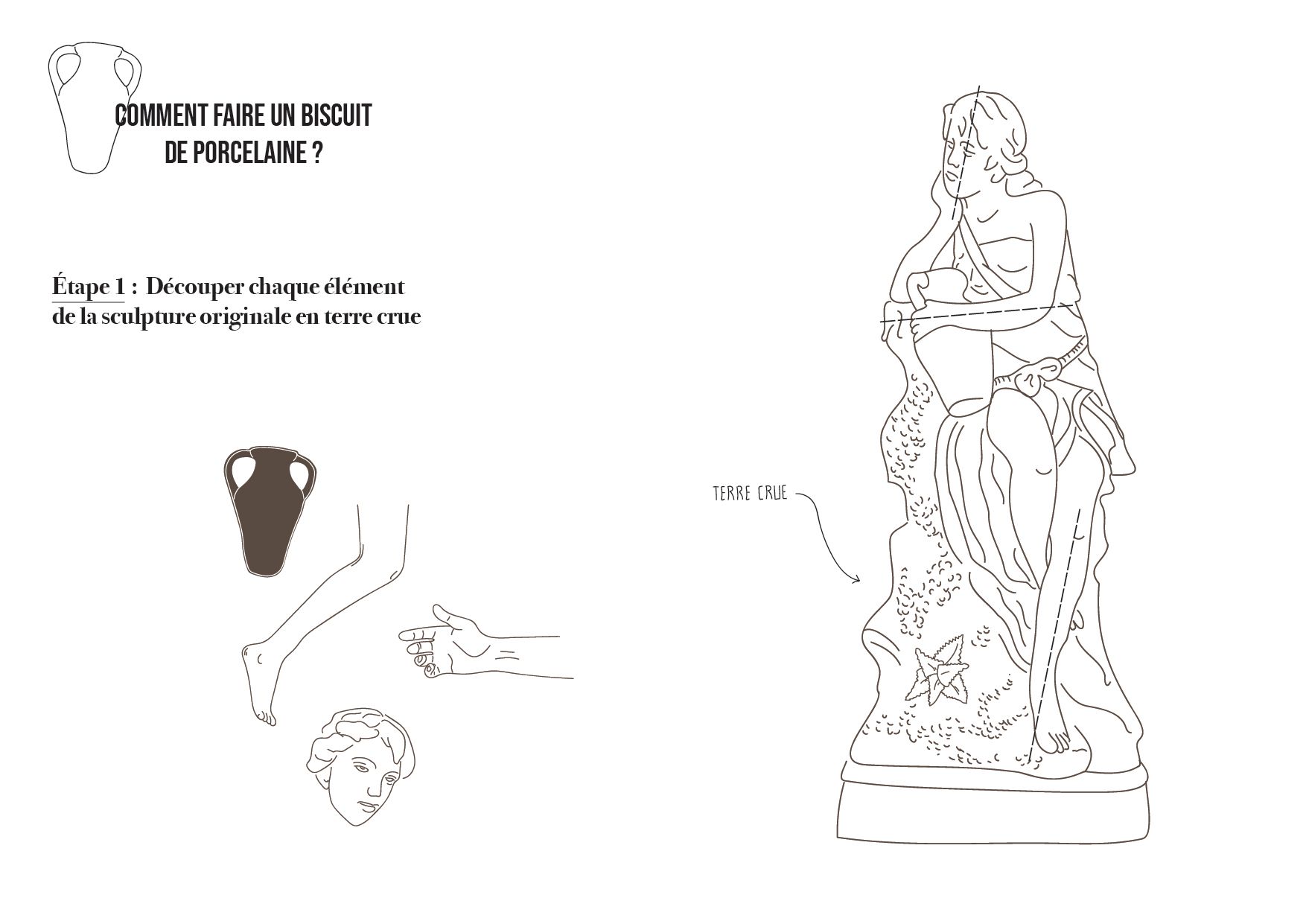

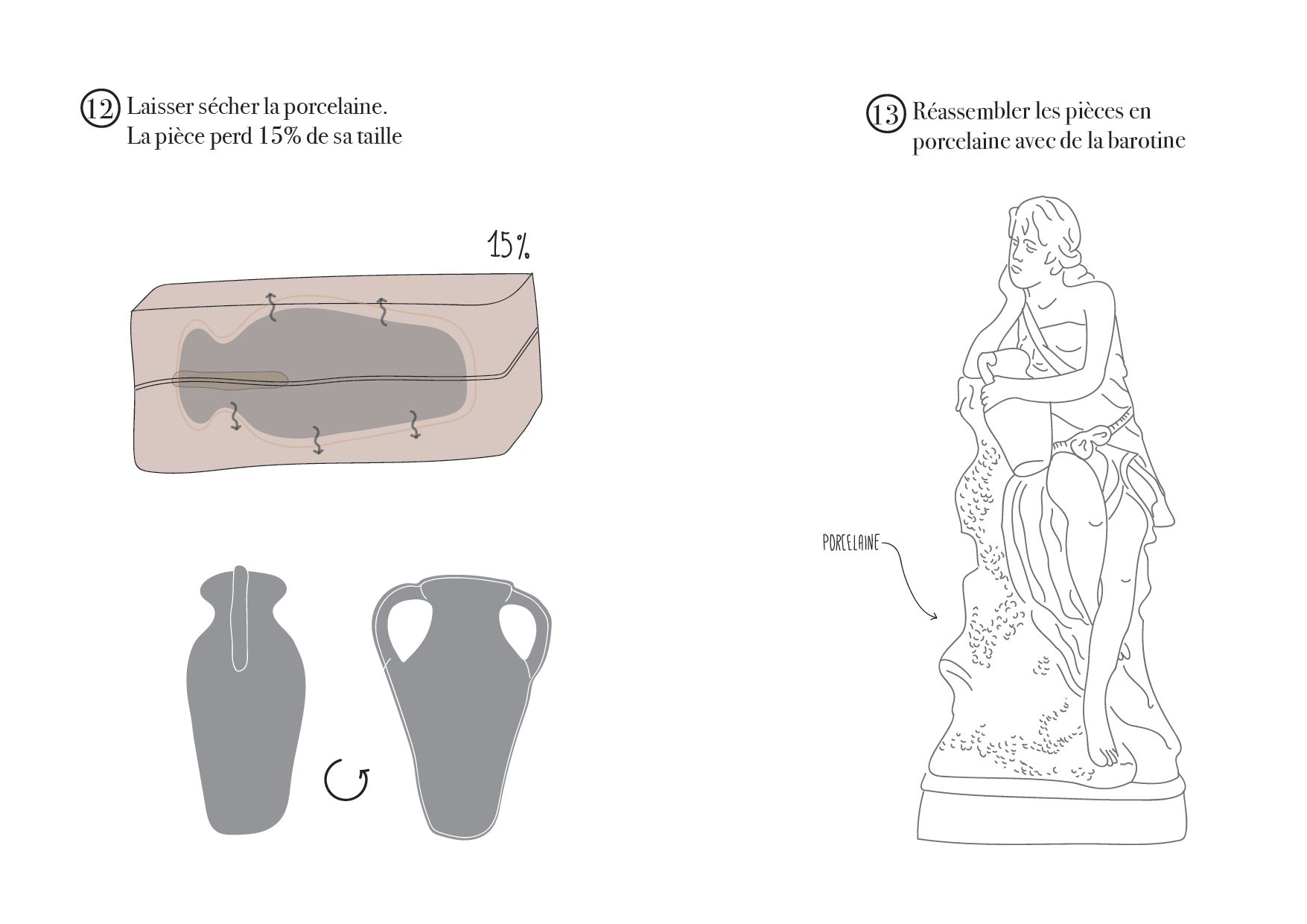

For the model, a renowned sculptor is often called upon. This was the case with Étienne Maurice Falconet in 1754, a sculptor at the Academy of Painting and Sculpture. This brings prestige to the workshops and attracts inspired talent to work with a master. Nowadays, manufacturers often collaborate with contemporary artists to create exceptional pieces and demonstrate innovation despite the use of an ancient technique. However, porcelain clay is not very plastic and cannot be sculpted directly. It dries out quickly, leading to numerous cracks and deformations. The sculptor must therefore create a model to be used for molds. The model is generally 15% larger than the final piece to account for successive shrinkage. This initial sculpture is delivered in raw clay, as it will be cut into different pieces to make the molds.

We'll take impressions of the different pieces to create a first set of molds. For a bisque, we make between 10 and 80 molds depending on the complexity of the model. This allows us to capture all the details of the figures. What you need to understand is that the artisan will create two sets of molds (or rounds of molds) to produce the artwork: plaster molds and clay molds .

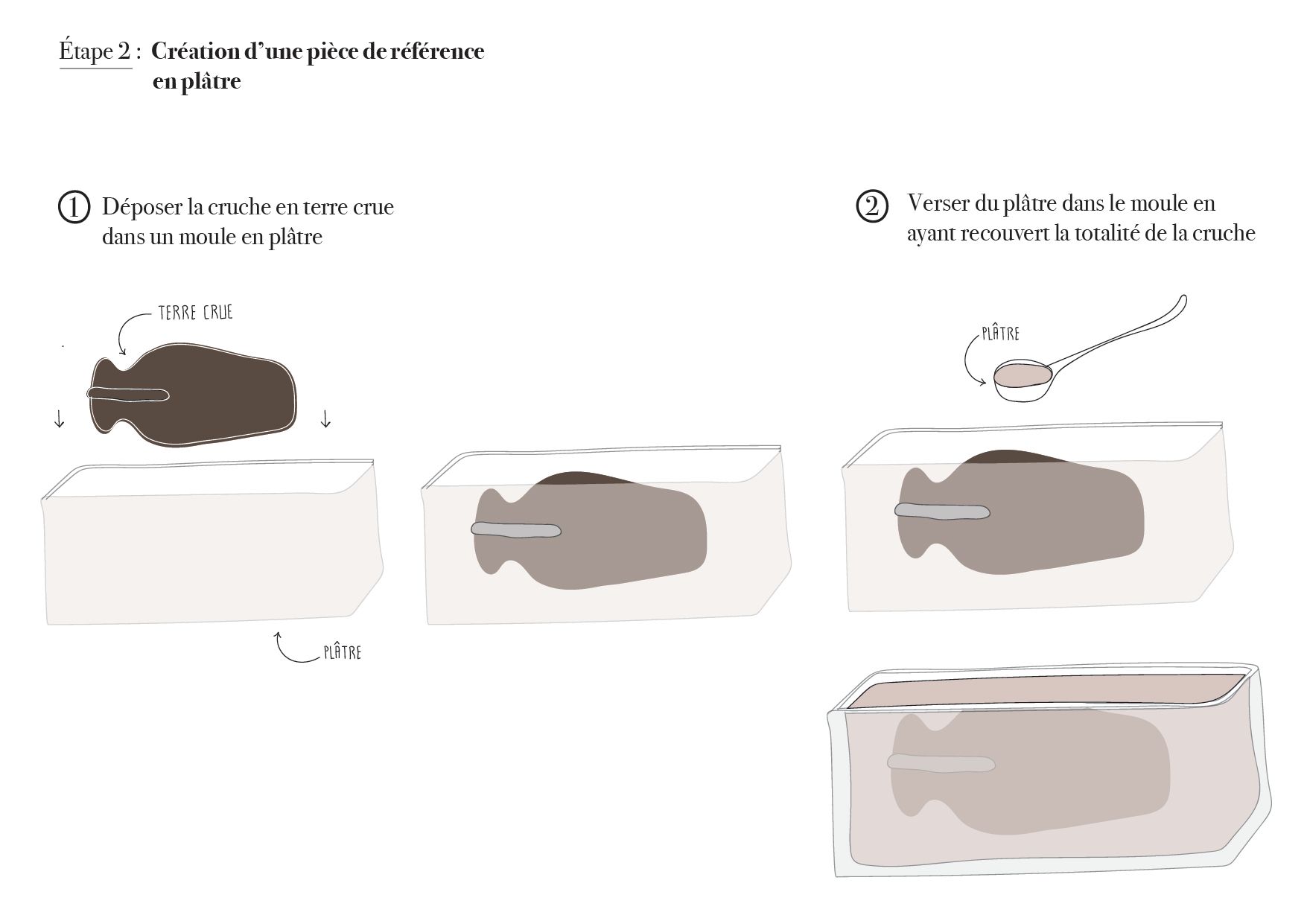

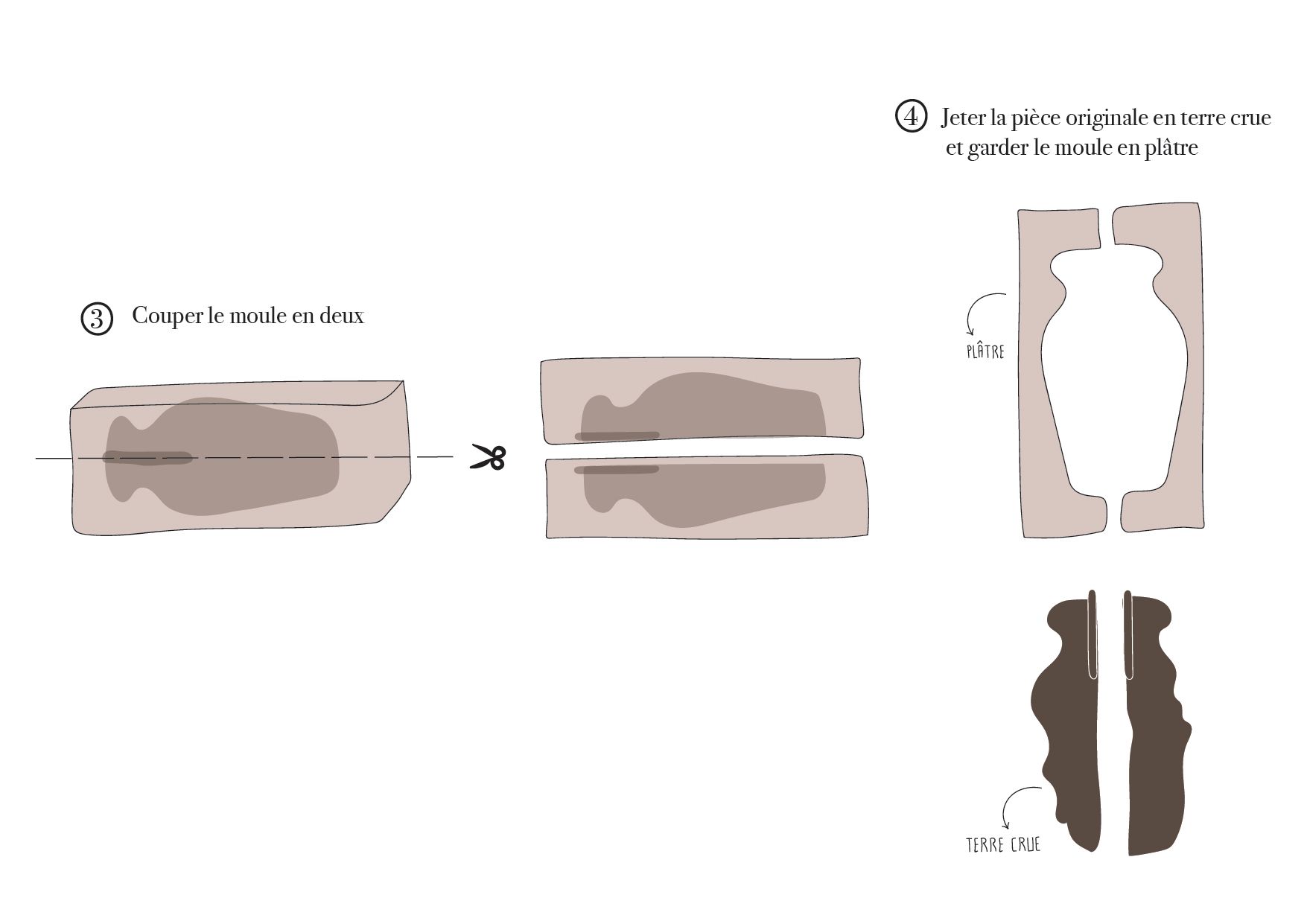

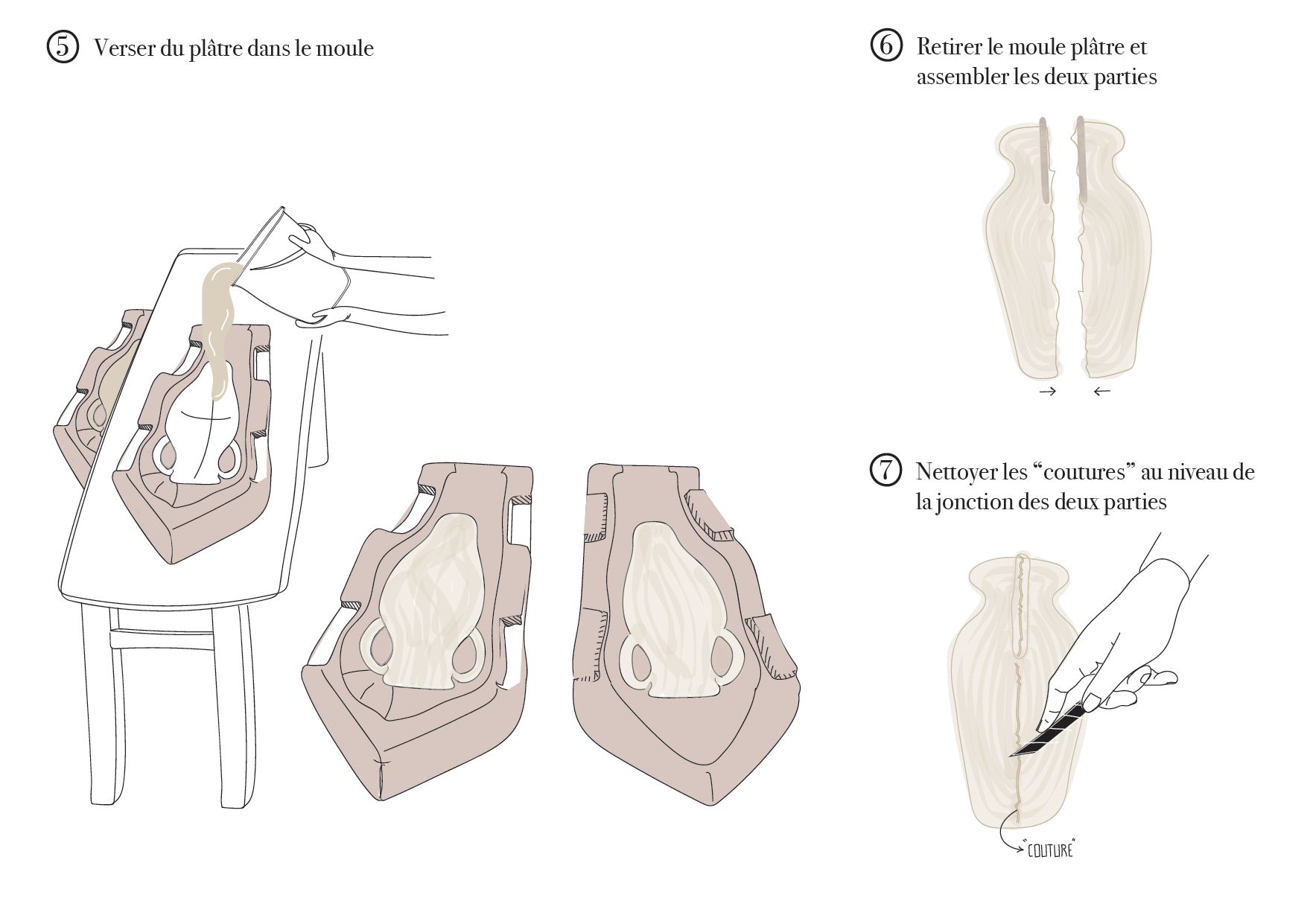

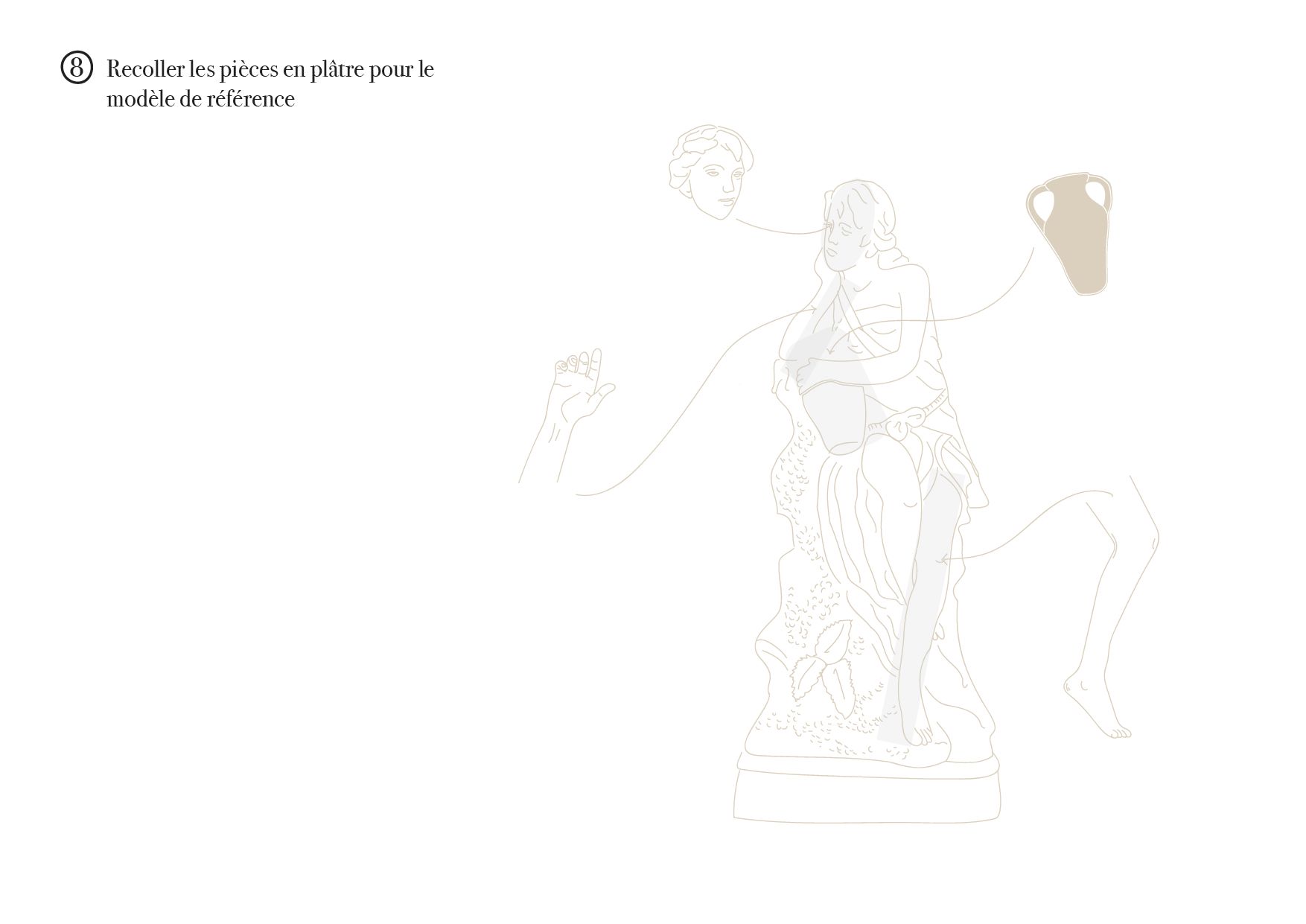

Plaster molds will be used to recreate the plaster sculpture that will serve as a model for the mold maker. To facilitate demolding, the model is coated with a thin layer of lubricating soap. Then, powdered plaster is sprinkled into a container of water. This is then spooned around the model and polished with a blade and fine sandpaper. The whole thing is soaped and dried. We now have our first molds. All the pieces obtained are retouched to give them the finesse of the original sculpture. The seams, which are the lines at the joints of the two pieces of the mold, are removed.

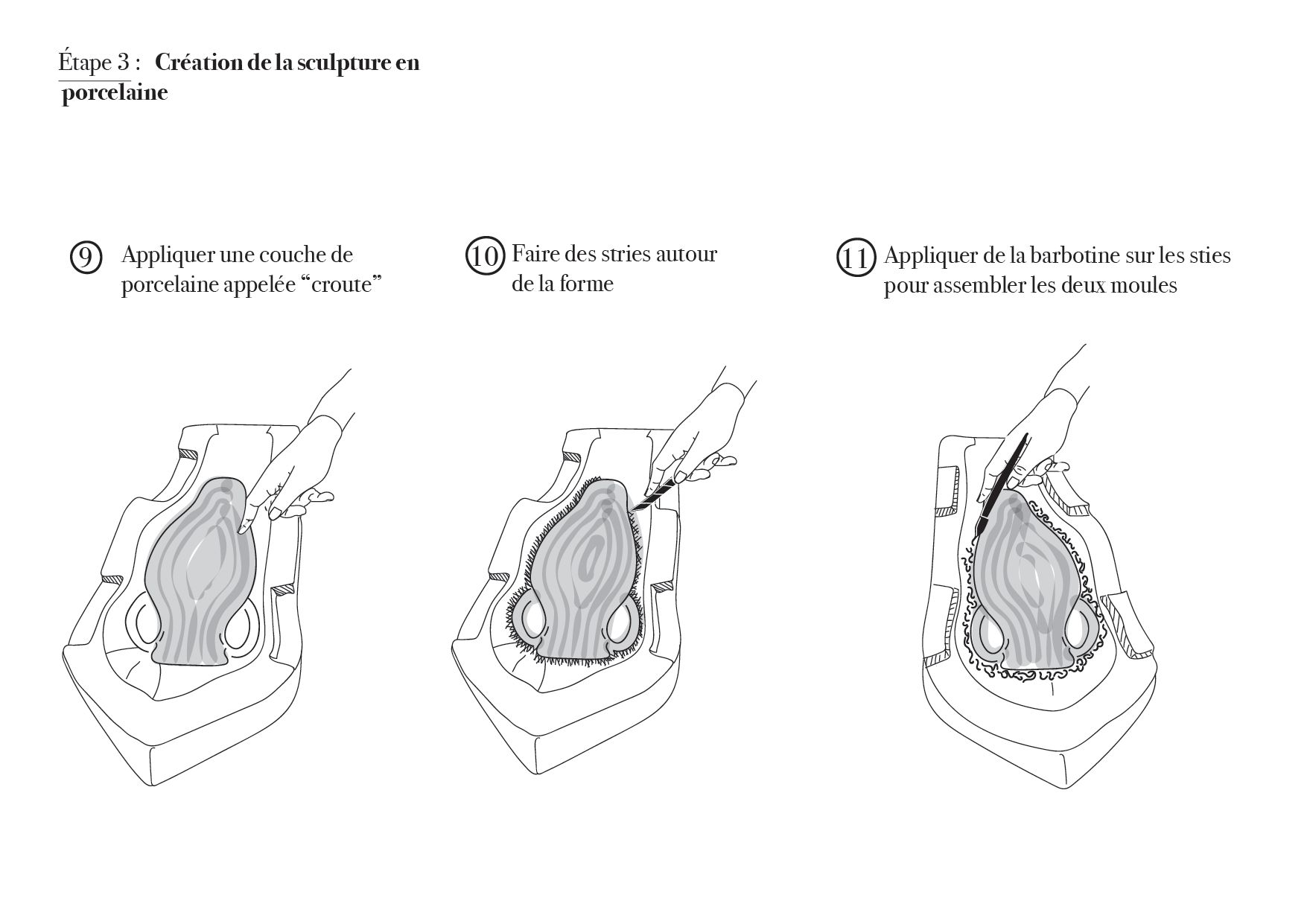

From this model, the clay molds , which are used to create the actual artwork. Each of these molds has a limited lifespan of 15 to 20 uses before losing precision or porosity. A thin layer of porcelain clay , about 5 to 8 mm thick, called a crust, to one half of the mold. This allows all the details to be captured. The crust is compressed first with a sponge and then by hand. To give the piece more strength, certain areas are reinforced with small balls of clay to achieve the final thickness. Now it's time to join the two pieces. The mold maker/repairer scores and coats the joints with slip. Once the mold is closed, they strike it with a leather-cushioned mallet to ensure the two parts adhere properly.

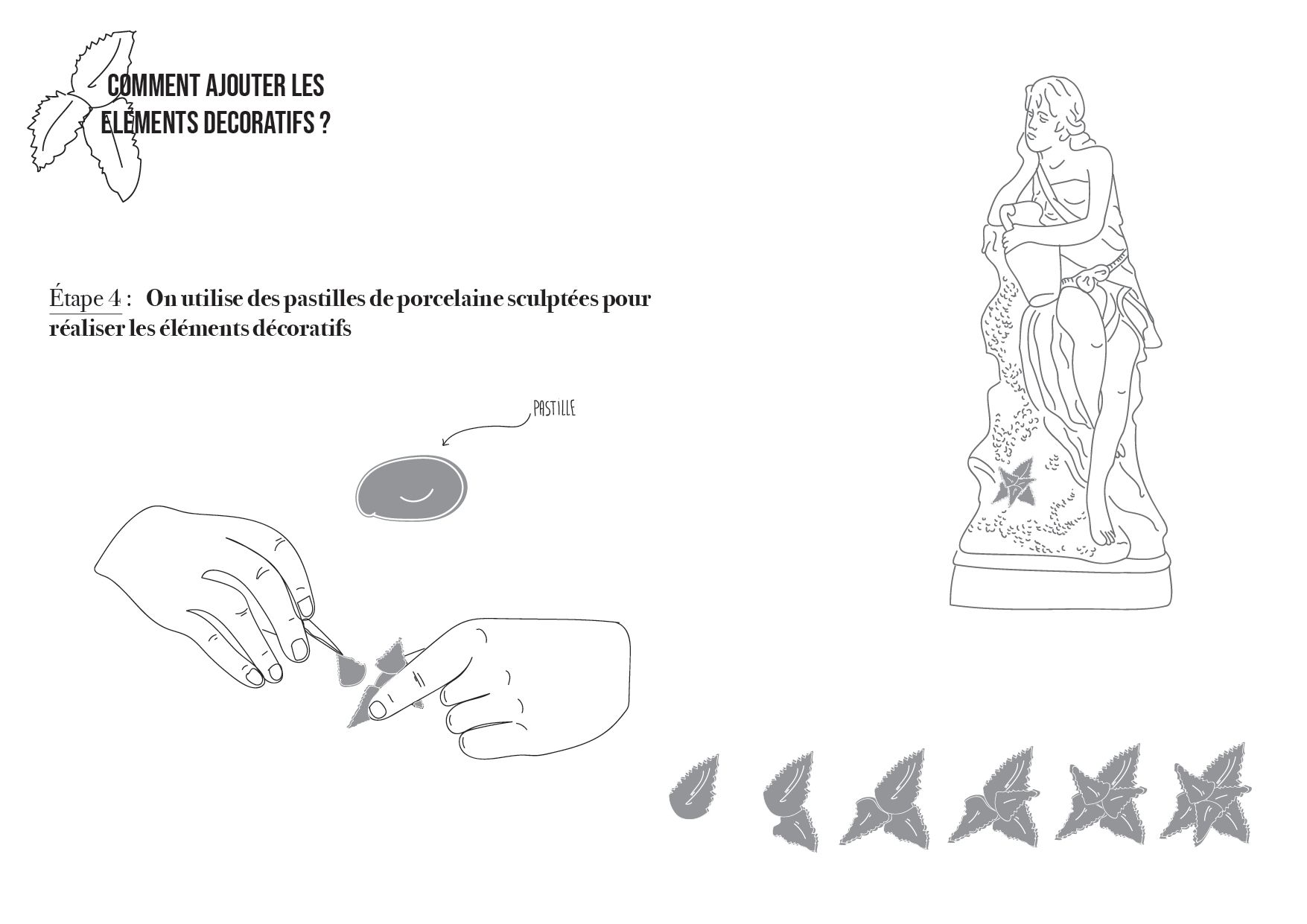

This is where the use of plaster comes in. Due to its porosity, it absorbs the water from the porcelain paste. This process, known as shrinkage, causes the porcelain to contract and become firmer. This allows for demolding without risk of breakage or material loss. The resulting pieces are kept in a humid box before being assembled and finished. At this stage, the craftsman creates small decorations, such as flowers or foliage, using the pastillage technique . He uses small porcelain discs that he hand-carves to create decorative elements.

The firing will take place several weeks later to allow the piece to dry. The artisan will then place supports to prevent warping in the kiln. In the 18th century, round, wood-fired brick kilns were used. Today, gas kilns are used. The kiln's temperature rises gradually, and it could take up to a week to reach the maximum temperature of between 1245°C and 1400°C. Today, the time is closer to 24 hours. This slow rise prevents the biscuits from exploding, which can occur due to sudden temperature changes.

Once the piece is fired, the work isn't finished. The mold maker must smooth out the seams and retouch any lost details, using the plaster model as a reference. This process is called repair, hence the name of the craftsman. His sculpting work makes each piece unique, despite the molding process, since the craftsman works the material himself. The quality of the final object depends heavily on the mold maker's care. Finally, he polishes the finished piece with a hard stone to give it its full luster.

Conclusion

Conclusion

The art of biscuit porcelain is long and meticulous. A single biscuit figure representing one person takes approximately nine months to complete. Groups can take up to a year. The pieces we have today bear witness to the great precision of manufacturers worldwide throughout the centuries in which biscuit porcelain has been produced. Decorating one's home with a piece of biscuit porcelain means owning an exceptional object that reflects a long history of European craftsmanship. Between economic competition and the pursuit of beauty, biscuit porcelain, though white, has shown us a wide range of colors.